1

/

of

8

Shenhaiex

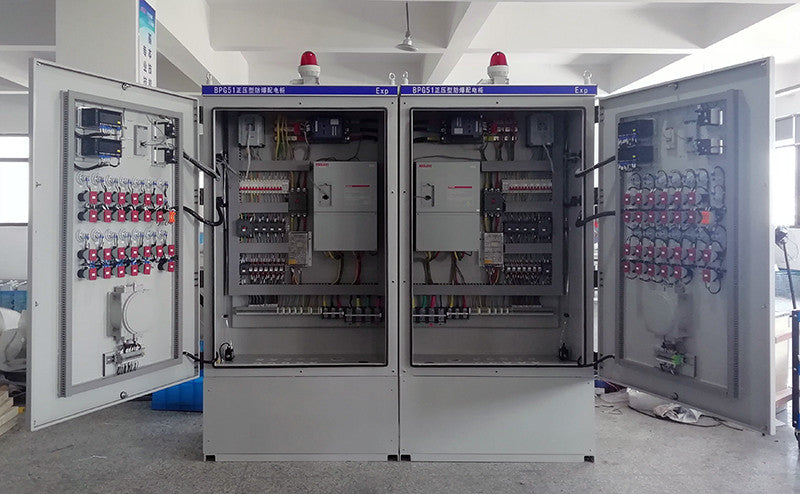

Explosion-proof pressurized enclosures BPG51

Explosion-proof pressurized enclosures BPG51

Regular price

$9,999.00 USD

Regular price

Sale price

$9,999.00 USD

Unit price

/

per

Couldn't load pickup availability

I. Working Principle

Explosion-proof pressurized enclosures operate by continuously introducing clean protective gas (such as compressed air or inert gas) into a sealed cabinet body. This maintains a constant internal pressure higher than the external environment (typically 50–1000 Pa), creating a micro-positive pressure state. This prevents external explosive gases or dust from entering the cabinet. Based on pressure maintenance methods, they are classified into two types:

- Positive Pressure Ventilation Type: Protective gas flows continuously to maintain constant pressure and flow rate3.

-

Positive Pressure Compensation Type: Utilizes solenoid valves for intelligent control of gas inflow/outflow, eliminating the need for continuous ventilation311.

When abnormal pressure occurs (e.g., below 50 Pa or above 1000 Pa), the automatic control system triggers audible and visual alarms, automatic gas replenishment, or power-off protection15.

II. Core Structural Components

-

Cabinet Body

- Material: Constructed from welded high-quality steel plate or stainless steel. Surface treated with shot blasting and electrostatic powder coating, achieving a corrosion resistance rating of WF124.

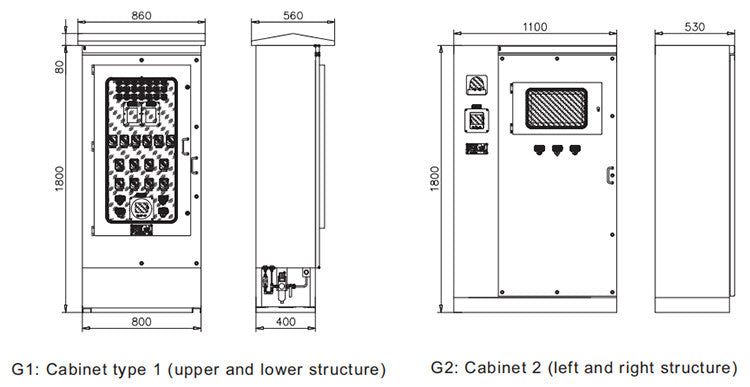

- Chamber Design: Divided into a positive pressure chamber (housing non-explosion-proof components) and an auxiliary chamber (containing the control system). Some designs feature left-right dual chambers to isolate high/low-power equipment, optimizing heat dissipation and maintenance34.

-

Automatic Control System

- Monitors pressure, temperature, and gas concentration in real-time. Features linked alarm (triggered below 50 Pa) and pressure relief (triggered above 1000 Pa) functions15.

- Equipped with safety interlock devices: Door opening automatically cuts power; power is only restored after door closure and completion of air exchange211.

-

Ventilation and Filtration System

- Air intake/exhaust ports designed based on gas density. High-efficiency filters remove airborne particulates and harmful gases11.

- Air exchange requirements: Zone 1 requires displacement of 7 times cabinet volume; Zone 2 requires 5 times1.

- Power Distribution System: Supports installation of standard electrical components, instruments, frequency converters, etc., with no explosion-proof rating restrictions3.

III. Key Parameters

| Parameter Type | Typical Value / Range | Description |

|---|---|---|

| Operating Pressure | 50–1000 Pa | Alarm if below 50 Pa; Pressure relief if above 1000 Pa12 |

| Purge Time | ≥30 minutes | Mandatory ventilation before startup25 |

| Gas Source Requirement | Pressure 0.4–0.8 MPa, Flow Rate ≥7 m³/h | Requires clean, oil-free air29 |

| Explosion-Proof Level | Ex pz IIC T1–T6 | Suitable for Group IIA/IIB/IIC gas environments19 |

| Corrosion Resistance Level | WF1 | Corrosion resistance performance1 |

| Standard Dimensions | 800×600×2200 mm | Customizable up to 2000×1200×3000 mm910 |

IV. Operating Procedure

-

Startup Preparation

- Check gas source pressure (0.4–0.8 MPa), cabinet sealing integrity, and ensure no debris inside57.

-

Ventilation and Purging

- Initiate ventilation for ≥30 minutes after startup to displace potential explosive gases within the cabinet5.

-

Pressure Monitoring

- Maintain working pressure between 80–400 Pa. Automatic gas replenishment activates under low pressure; power is cut if replenishment fails5.

-

Operation and Shutdown

- Monitor parameters in real-time during loaded operation. For shutdown: deactivate load first, then cut power and gas supply after 5 minutes57.

V. Application Scenarios

- Industries: Petrochemical, Pharmaceutical, Natural Gas, Coal Mining, Military, and other environments with explosion risks16.

- Hazardous Areas: Explosive gas atmospheres Zones 0/1/2; Dust atmospheres Zones 20/21/2218.

VI. Maintenance Requirements

- Regularly replace filters, inspect sealing strips, and check electrical connections7.

- Strictly prohibit: Storing flammable materials inside the cabinet, unauthorized structural modifications, or welding operations nearby7.

Note: The above specifications are designed according to the National Standard GB3836, ensuring stable operation within an ambient temperature range of -20°C to +40°C and at altitudes ≤ 2000 m

Share